I work at the intersection of design, engineering, and execution—where ideas become devices, tools, and experiences people rely on. From first sketch to final enclosure, I focus on building things that ship, last, and matter.

Plastic Part Design for Injection Molding

Project: Nizi Power – Universal Powerbank

Designing for injection molding is about getting everything right—from draft angles to fits and tolerances and tooling constraints. On the Nizi Power project, I engineered a durable enclosure in ABS, optimized for both thermal performance and manufacturing efficiency.

The result: fewer parts, faster assembly, and a housing that’s been mass-produced and battle-tested in the real world.

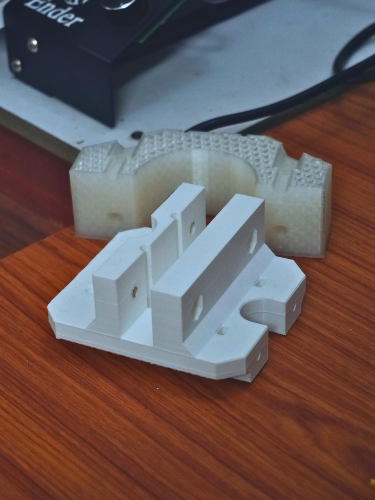

Design for Additive Manufacturing (DfAM)

Project: NoirCam – Thermal Instant Camera

NoirCam was built entirely around the possibilities of 3D printing. I used internal structures to keep the weight down and form complexity up—without compromising strength. The enclosure is tailored for FDM and resin workflows, making it easy to prototype and customize while staying functionally solid.

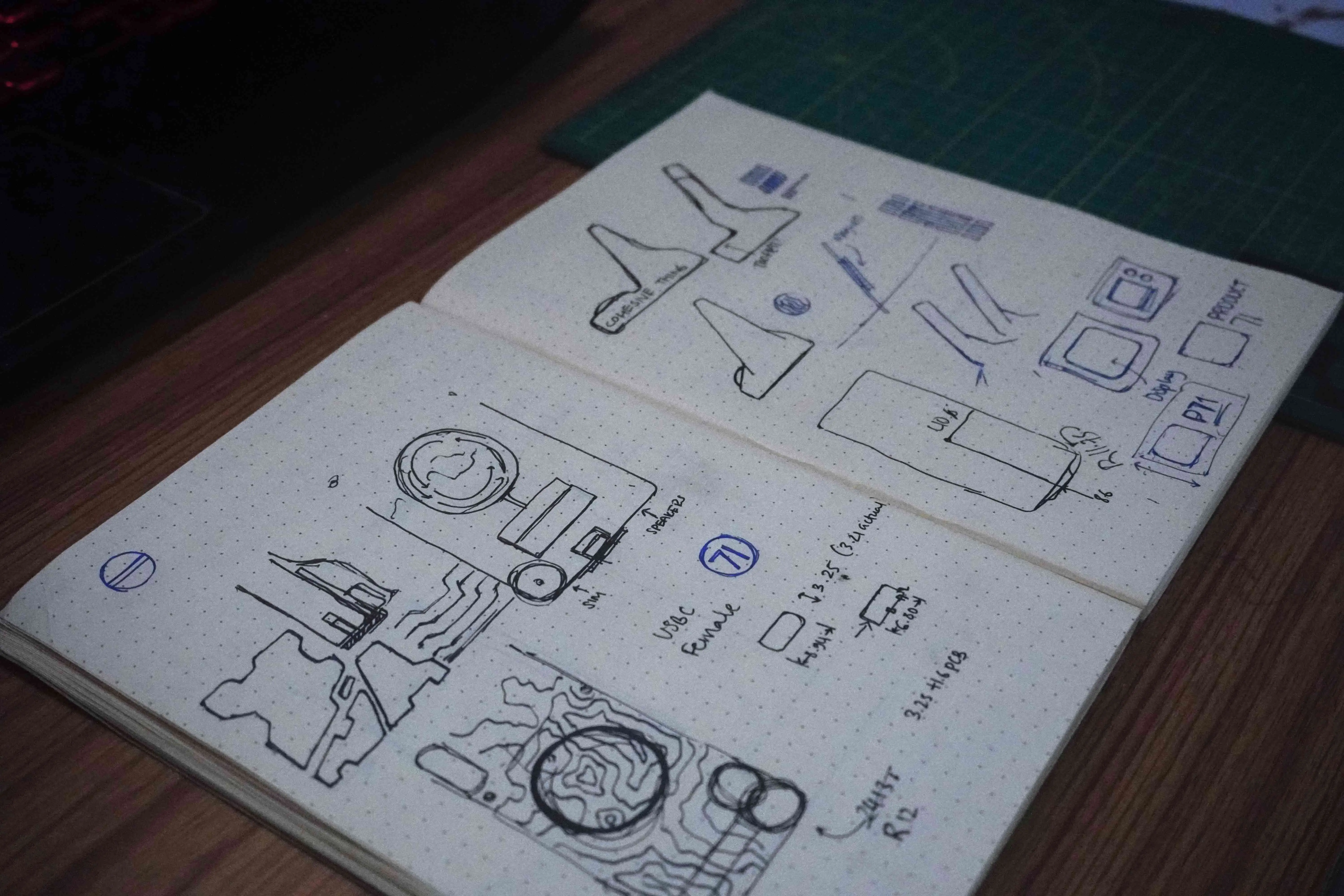

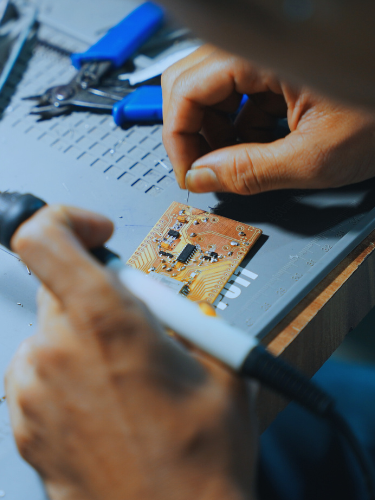

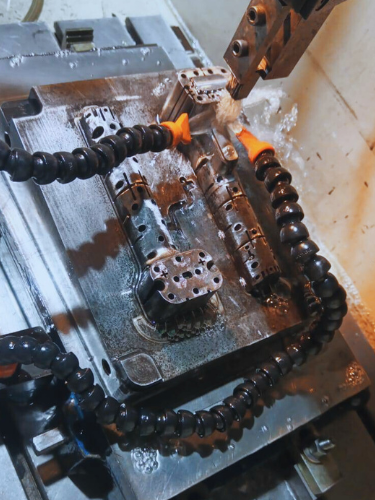

Rapid Prototyping

Project: DIY CNC & Custom Electronics Builds

Whether it’s a wireless charger dock or a camera hacked together from thermal printer and an ESP32, I constantly prototype my ideas. I combine 3D printing, CNC machining, and laser cutting to move fast, test often, and refine designs long before they go near production.

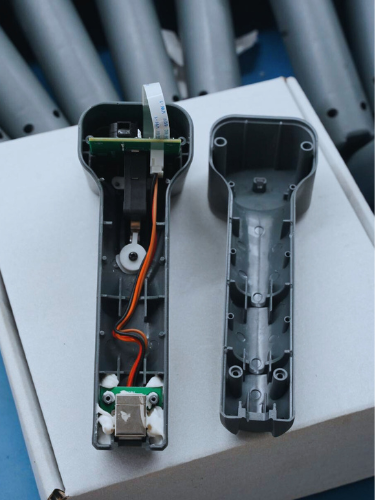

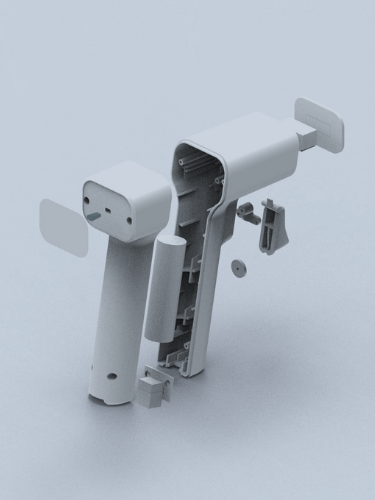

Design for Assembly (DFA)

Project: Nizi Scan – Barcode Scanner

I designed Nizi Scan from the ground up for injection molding, testing multiple FDM and SLA prototypes across different users and hand sizes. I engineered the enclosure with internal ribs, guide pins, and precision-aligned walls to ensure robust assembly. I also developed a custom-tuned button mechanism that delivers a tactile click, setting it apart from typical barcode readers.

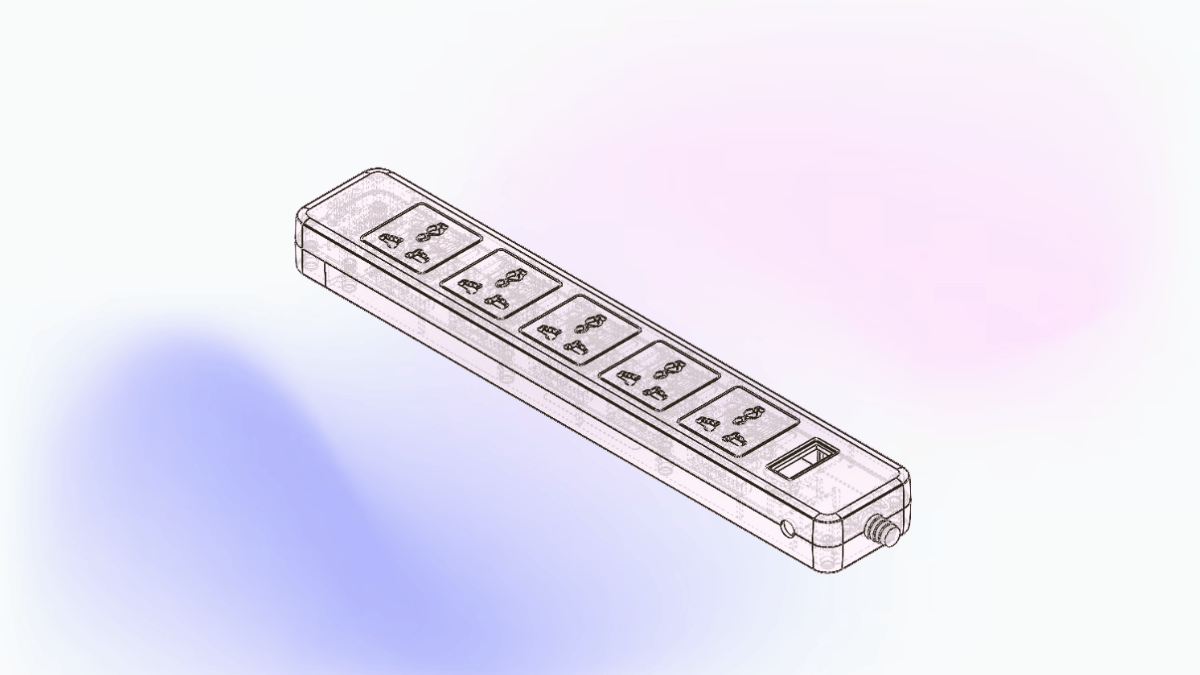

User-Centered Design

Project: PowerChain – 3500W Power Extension Board

I designed PowerChain for high-load, everyday use—where reliability isn’t optional. It combines overload protection, daisy-chainable ports, and a compact footprint without sacrificing plug clearance; even bulky adapters can sit side by side without collision. The L/N/E pass-through terminals make PowerChain modular and expandable—ideal for workbenches, studios, and homes. Internally, the enclosure features optimized ribs, guide pins, and parting lines to streamline injection molding and easy assembly.

Everything you’ve seen here started with a rough idea. If you’ve got one of your own, I’d love to hear it.

Let's Build Something Real

I design and build real products—things that get made, used, and remembered. If you need a hands-on designer who gets the details right, let’s talk.

Send Email →