Ever since I got into CNC machining, I’ve dreamed of designing my own desktop CNC machine. Something compact, precise, and capable of handling various materials—basically, a mini powerhouse for my workshop. Inspired by the minimalist yet robust designs from Langmuir Systems, I set out to create a CNC that’s both functional and stylish. Here’s the tale of how I brought this idea to life, with all the ups and downs along the way.

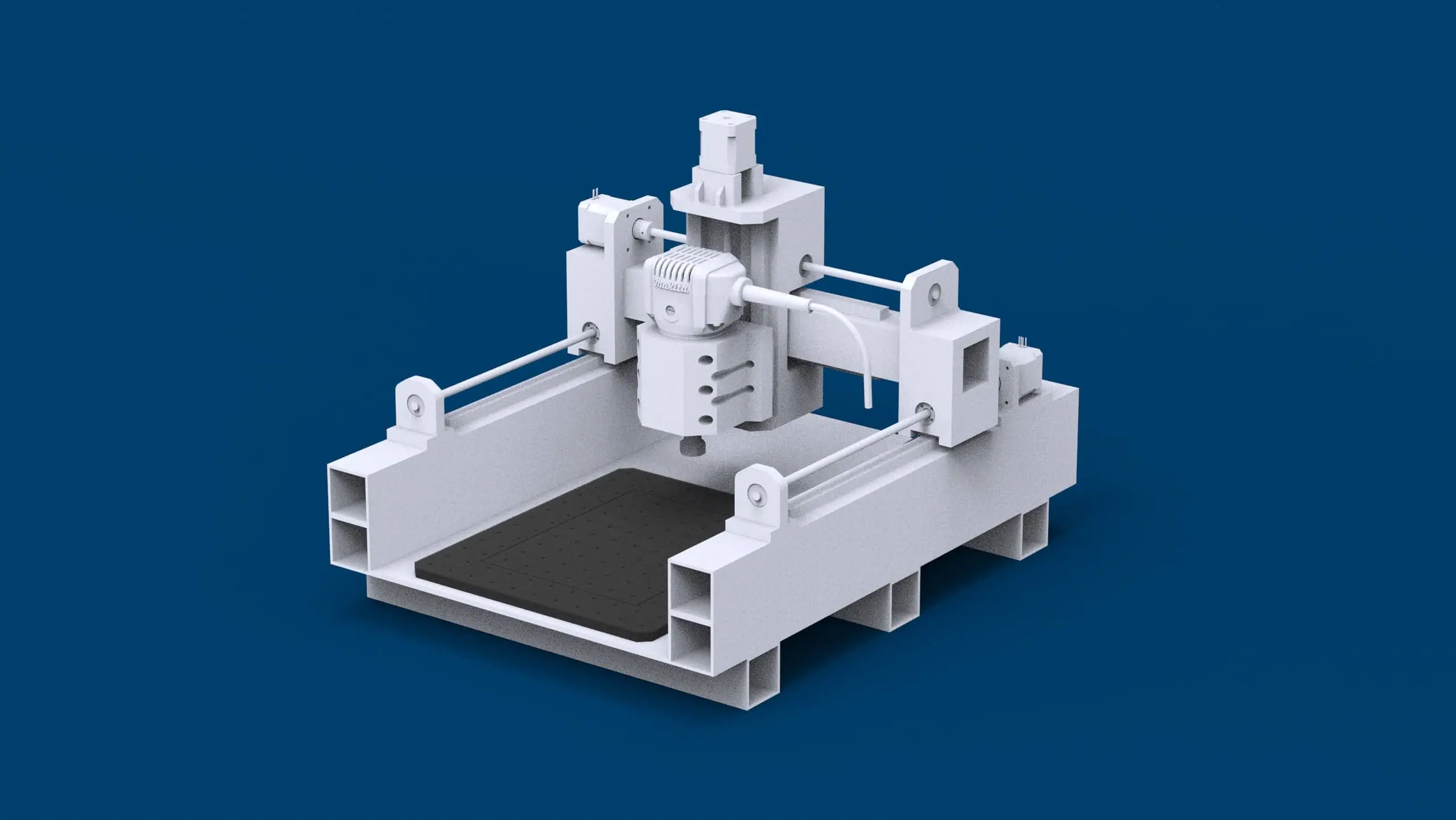

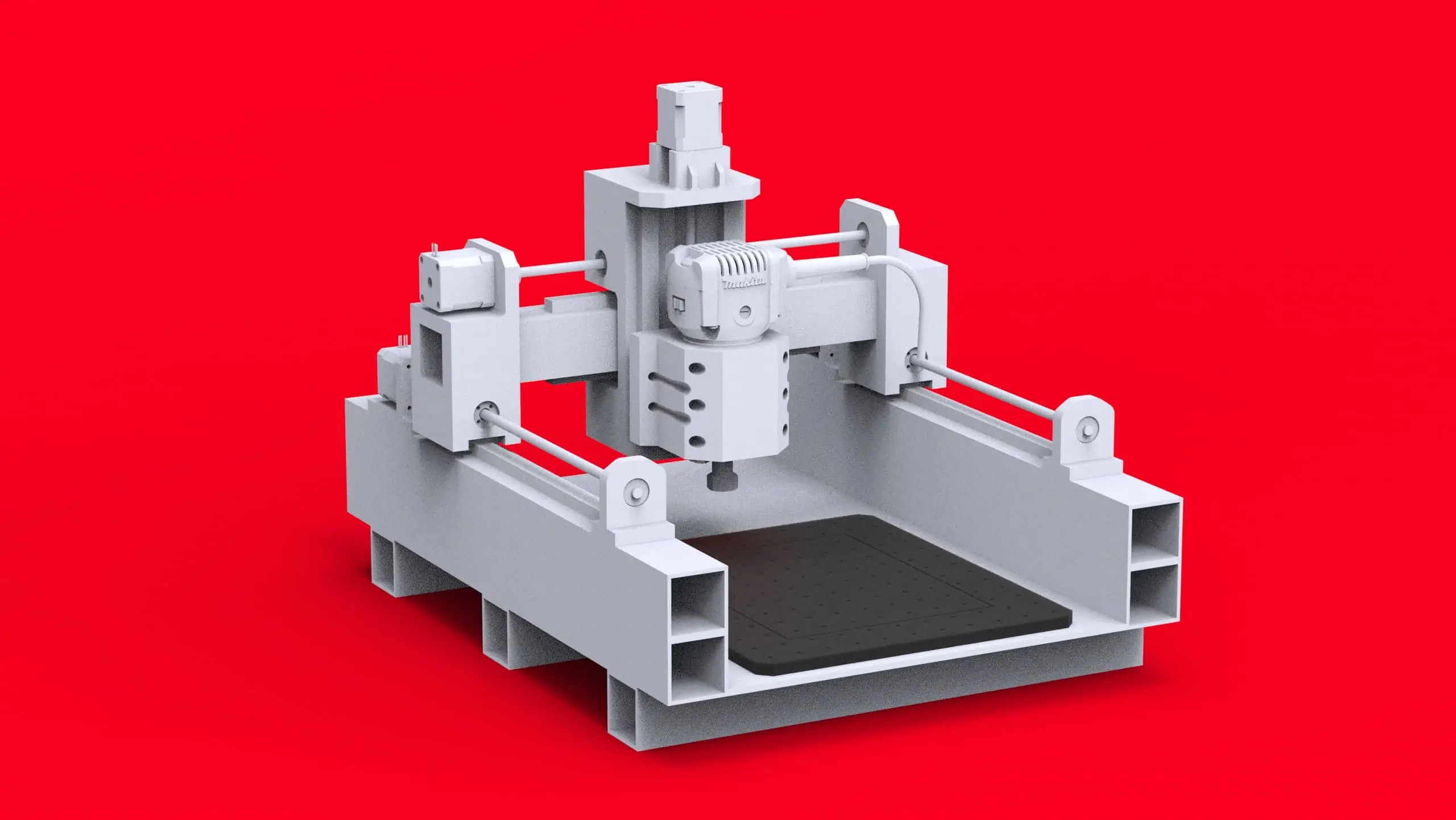

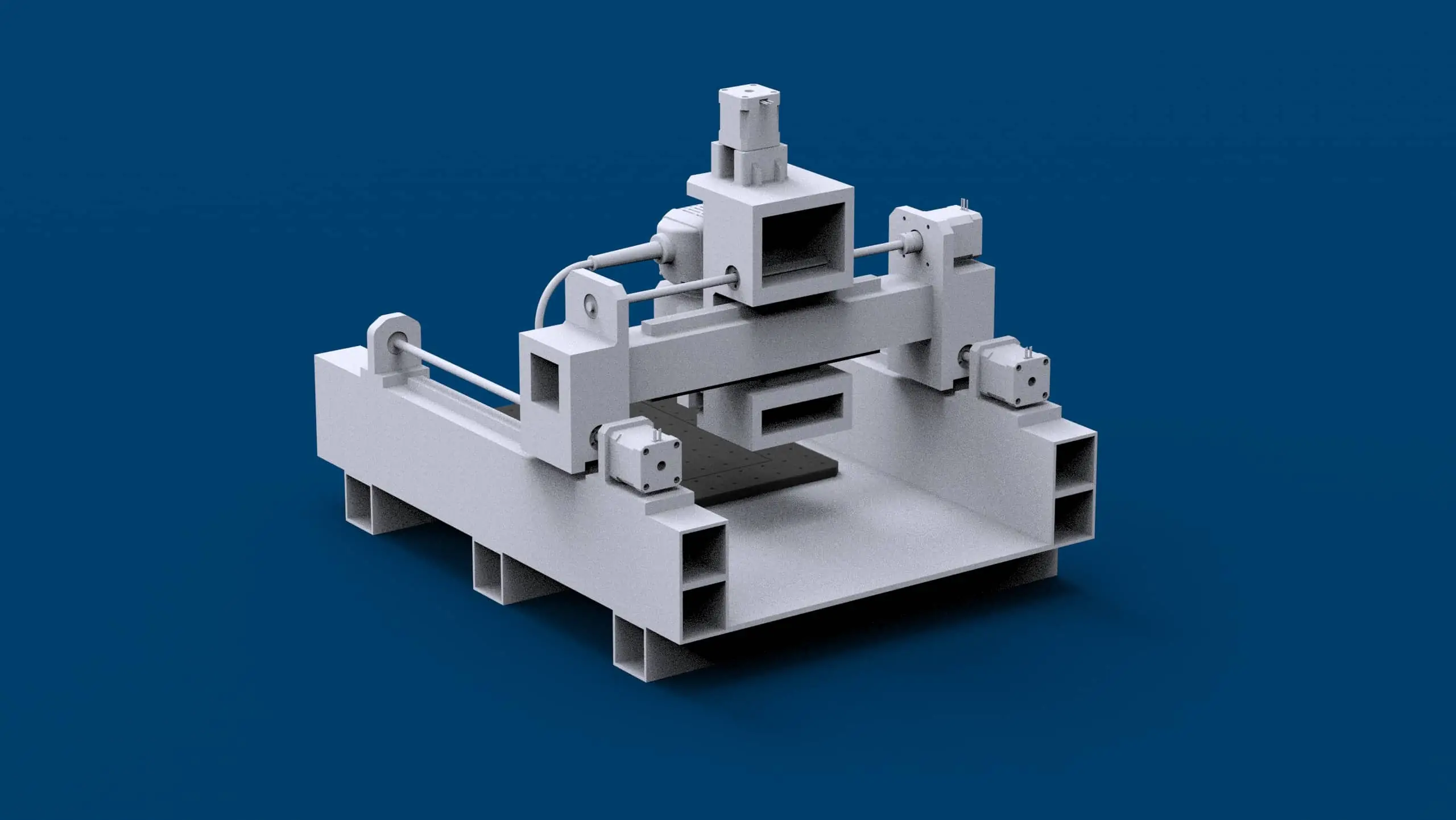

The Design: Structural Steel for Stability Originally, I considered using an epoxy granite mixture for the machine base due to its excellent vibration-damping properties. However, the high cost of epoxy resin led me to a more economical choice: a structural steel frame made of square tubes. This material provides a sturdy foundation and can be easily filled with a polyester resin concrete mixture if additional rigidity or vibration damping is needed. The versatility of this design means that I can always upgrade or modify it later based on the machine’s performance and specific project requirements.

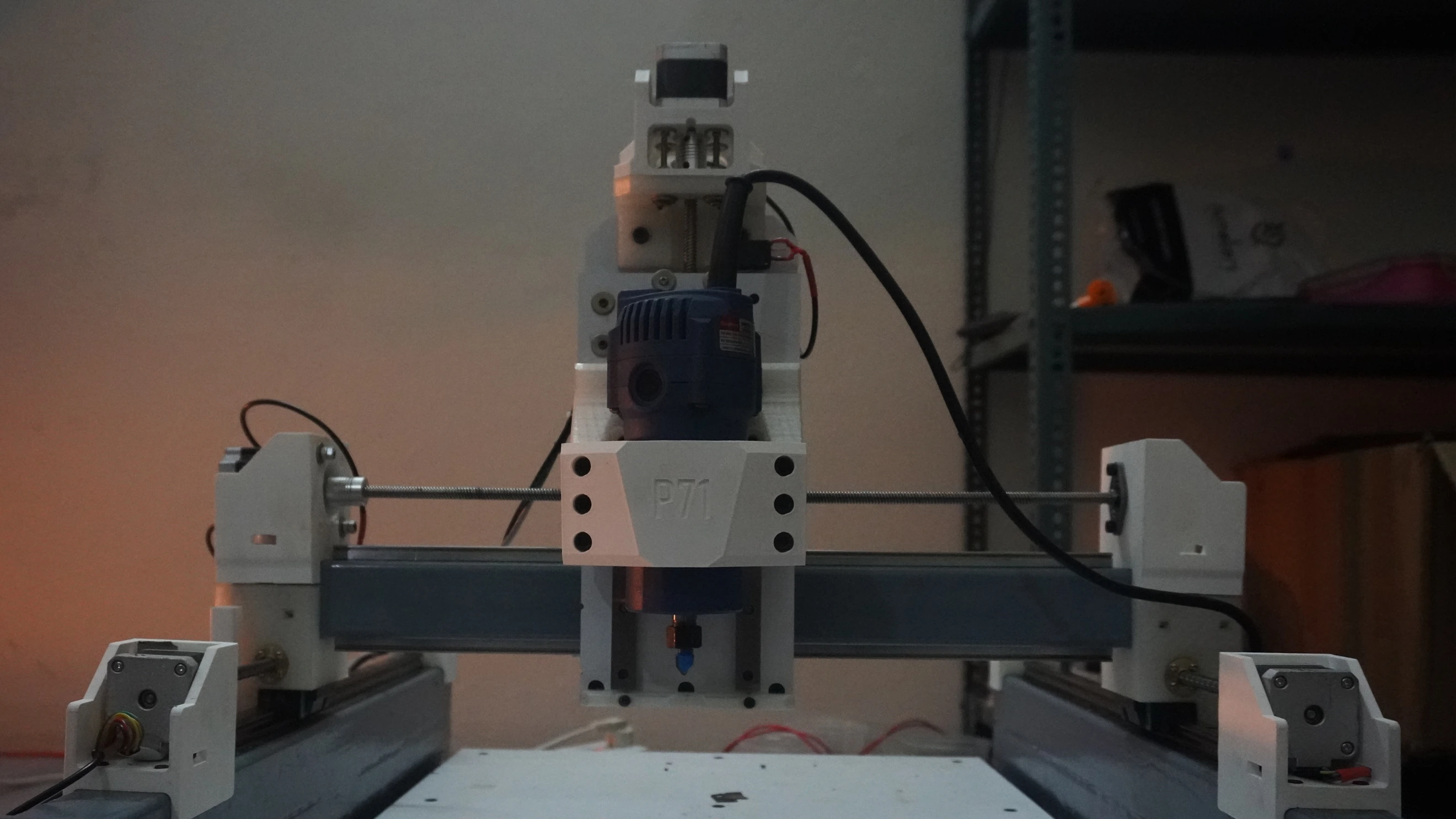

The Build: A Work in Progress

The CNC is still in the design phase, and I’ve shared the concept across various platforms to gather feedback and make necessary adjustments. The current setup includes a Makita wood router as the spindle, capable of cutting both wood and aluminum. However, I’ve designed the machine with future upgrades in mind, allowing for the installation of a standard spindle to tackle more demanding materials.

Precision and Calibration

Precision is a critical aspect of CNC machining. For DIY builders, achieving high accuracy involves meticulous calibration and maintenance. Key steps include tramming the machine to ensure the spindle is perpendicular to the bed and using high-quality end mills tailored to the materials being cut. For example, upcut and downcut end mills are essential for managing chip evacuation and surface finish. Compression bits are ideal for cutting laminates, ensuring smooth surfaces on both sides of the cut. It’s also crucial to regularly surface the table to maintain a flat and even work surface (Make: DIY Projects and Ideas for Makers) (Make: DIY Projects and Ideas for Makers).

Future Prospects: Upgrades and Enhancements

One of the most exciting aspects of building a custom CNC is the potential for upgrades. Whether it’s enhancing the machine’s rigidity, improving its motion control with upgraded motors and controllers, or even adding a more powerful spindle, the possibilities are endless. This project is not just about creating a tool but exploring the boundaries of DIY manufacturing and personal fabrication.

The journey of building a desktop CNC is a blend of engineering, creativity, and problem-solving. As I continue to refine the design and move toward the fabrication phase, I’m excited about the potential projects and applications this machine will unlock. Whether you’re a seasoned maker or a newcomer to the world of CNC machining, the key is to stay curious, keep experimenting, and enjoy the process.