In the realm of robotics, manipulators have always been a fascinating subject due to their versatility and precision. Among the many types of manipulators, spherical parallel manipulators (SPMs) stand out for their ability to perform complex rotational movements. Traditionally, these systems rely on motors and actuators to achieve precise control. However, there exists an intriguing class of non-motorized SPMs that demonstrate the fundamental principles of mechanical movement using only passive components.

The concept of a non-motorized spherical parallel manipulator revolves around simplicity and minimalism. Instead of using motors, these systems employ passive elements such as dowels, strings, and a clever arrangement of linkages to achieve the desired range of motion. The key idea is to create a structure that can manipulate a platform within a spherical workspace without the need for active control.

Design and Construction

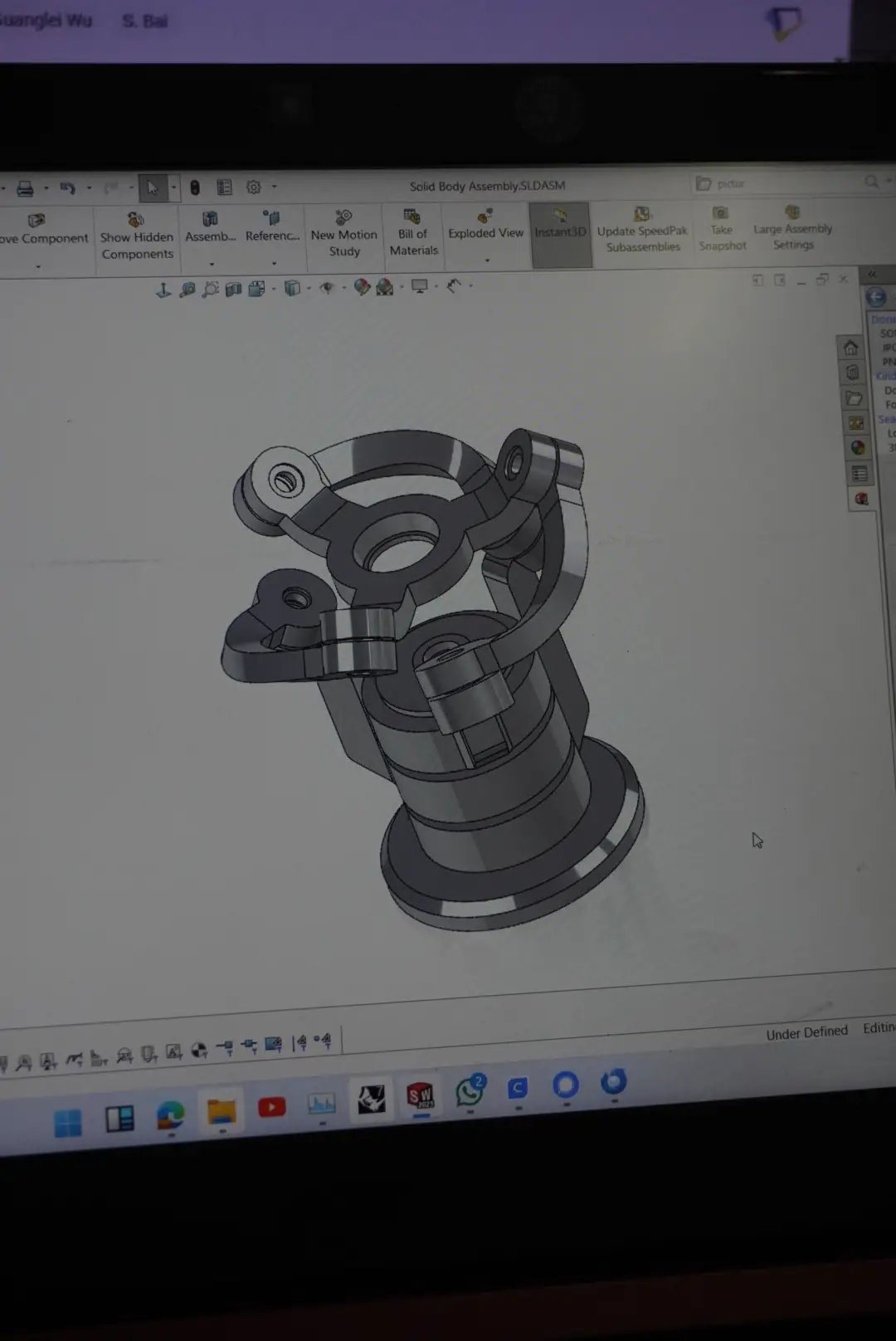

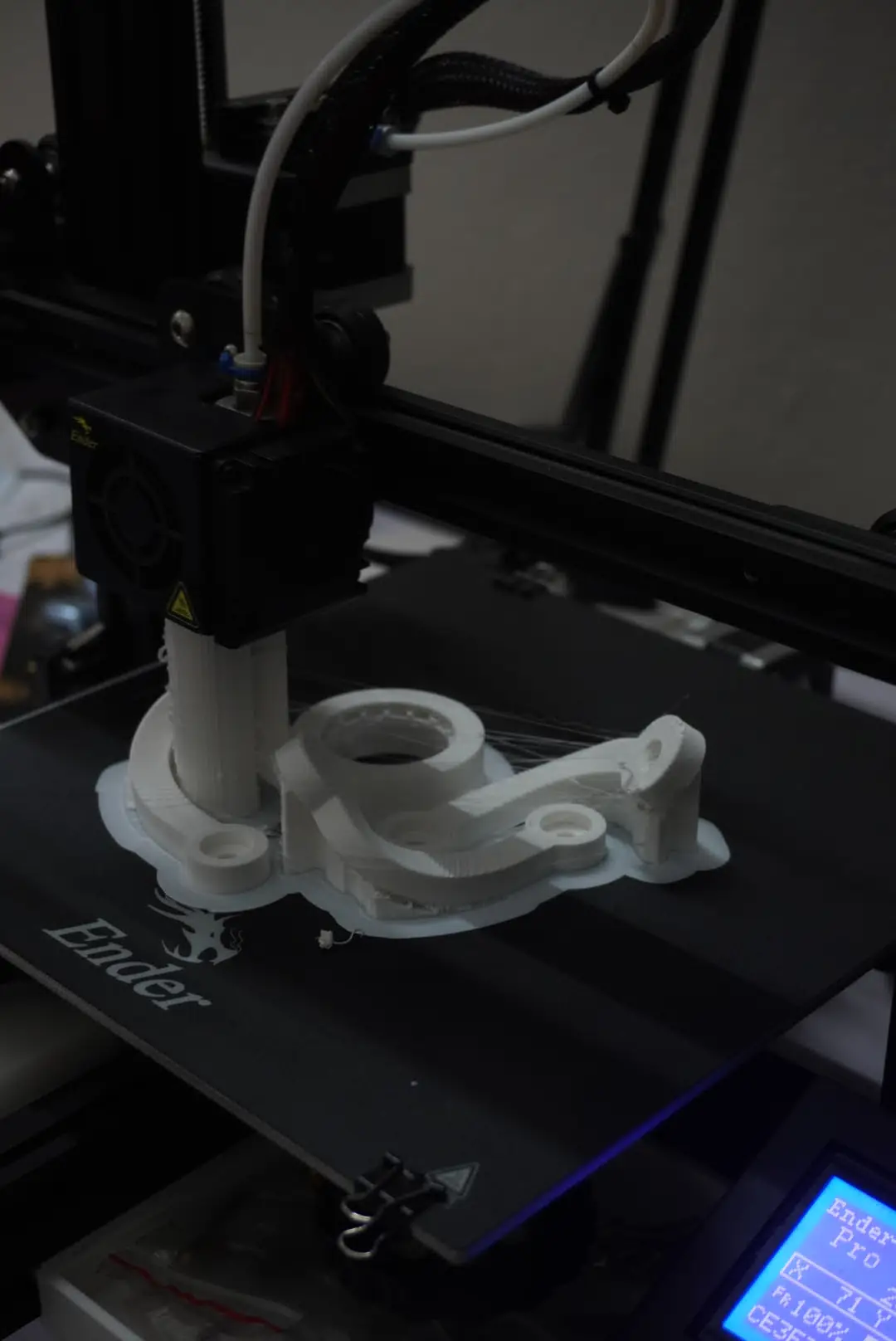

At its core, a non-motorized SPM consists of a base, a movable platform, and several linkages connecting the two. The base and the platform are typically triangular, providing a stable and symmetrical configuration. The linkages, often made from lightweight materials like wooden or plastic dowels, are attached to both the base and the platform via simple pivots or hinges. Strings or fishing lines may be used to maintain tension and guide the motion.

The absence of motors means that the platform’s movement is driven by external forces, such as gravity or manual manipulation. This passive nature can be advantageous for certain applications, particularly where simplicity, cost-effectiveness, and safety are paramount. For example, educational demonstrations and low-cost prototyping can benefit greatly from such a design, as it allows for the exploration of fundamental robotic principles without the complexities and costs associated with motorized systems.

Applications and Limitations

While non-motorized SPMs may lack the precision and control of their motorized counterparts, they offer unique insights into the mechanics of parallel manipulation. These systems can serve as excellent educational tools, providing students and enthusiasts with a hands-on understanding of kinematics and dynamics. Additionally, in environments where power sources are limited or the use of motors is impractical, passive SPMs can offer a viable alternative.

However, the simplicity of non-motorized SPMs comes with certain limitations. The lack of active control mechanisms restricts their ability to perform precise and repeatable tasks. The range of motion and load capacity are also typically lower compared to motorized systems. Despite these constraints, the elegance of a well-designed non-motorized SPM lies in its ability to demonstrate complex motion through simple mechanical principles.

Personal Experience and Resources

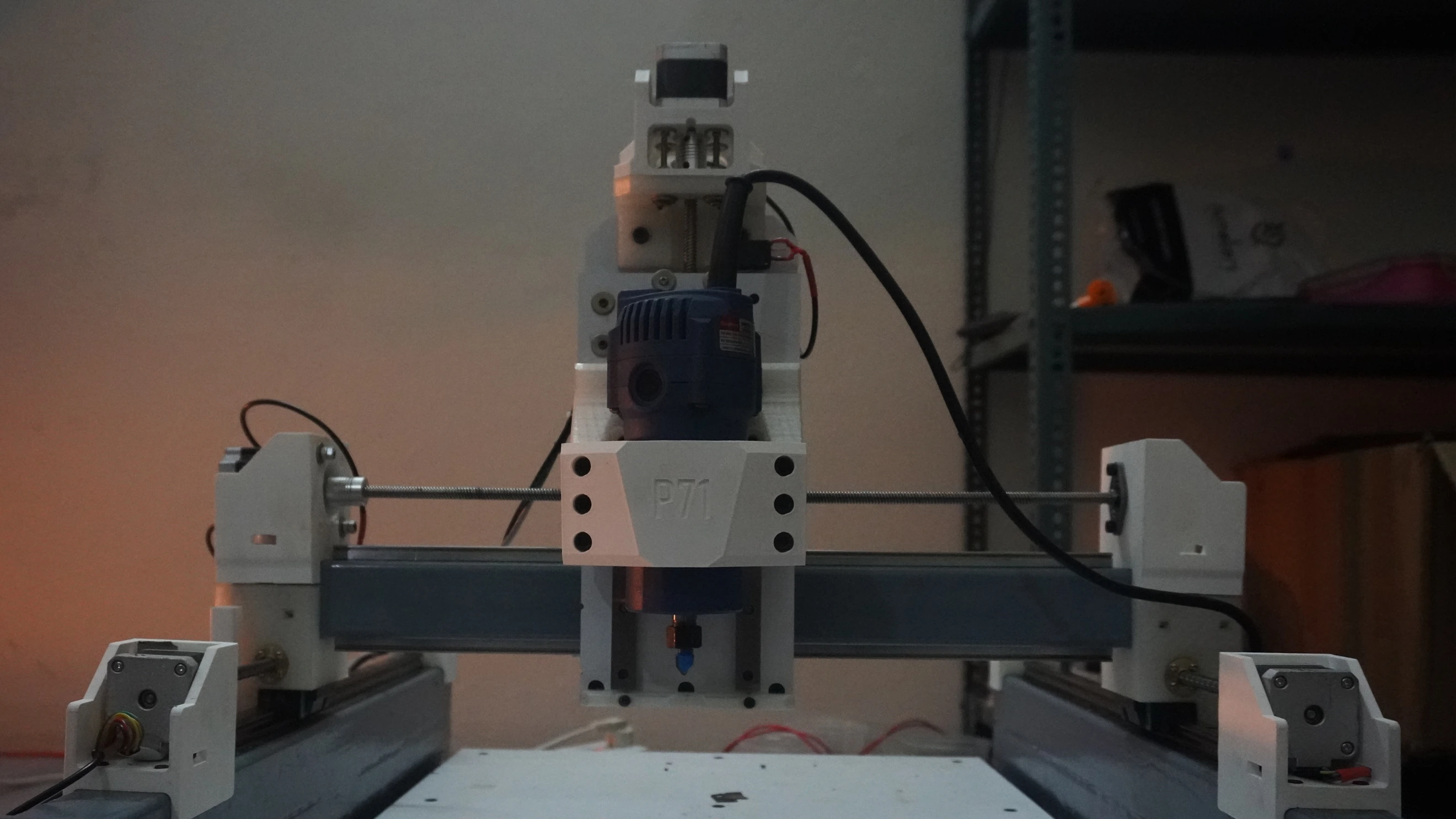

In my own journey, I explored the creation of a non-motorized spherical parallel manipulator and found it to be a deeply enriching experience. The process taught me about the beauty of passive systems and the elegance of simple mechanical design. For those interested in seeing how I built my own version, you can watch the YouTube video I made. It showcases the construction process and the fascinating motion capabilities of the manipulator.

For anyone eager to try building their own, I’ve also shared the 3D printable files. These files provide all the necessary components to create a non-motorized SPM, allowing you to explore this concept firsthand and potentially add your creative modifications.

The exploration of non-motorized spherical parallel manipulators is a fascinating journey into the essence of robotic motion, offering unique insights into the mechanics of parallel manipulation through simple mechanical principles.

These devices challenge the conventional notion that complex tasks require complex solutions. Whether for educational purposes, low-cost applications, or sheer curiosity, non-motorized SPMs offer a unique perspective on the art and science of manipulation. I encourage you to experiment with your designs and share your experiences, contributing to a growing community of learners and innovators in the field of robotics.